PVC Coated Copper Pipe Manufacturer and Exporter in Qatar – Manibhardra Fittings

Manibhardra Fittings deals in manufacture and export of PVC coated copper pipes of excellent quality and based in Qatar. Copper’s high performing attributes are made even better by PVC coating, and it reflects a company that provides quality products in the market. Our pipes are perfect for use in a number of industrials and they come with great corrosion protection and high dependability that is valued by professionals. At Manibhardra Fittings we work very hard at the quality and satisfaction of the customers by delivering the best quality of equipments. You can count on us and rely on us for PVC coated copper pipe requirements in Qatar.

PVC Coated Copper Pipes Types in Qatar

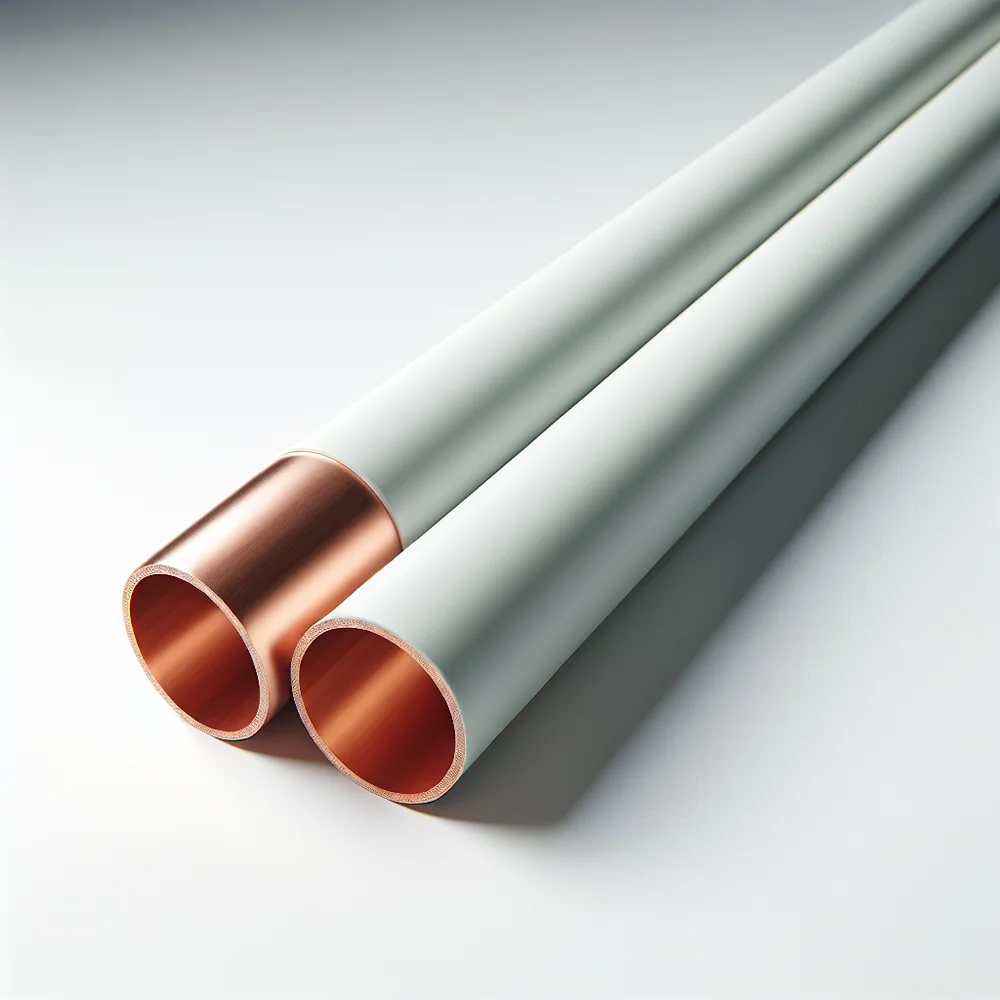

There are two basic categories of PVC coated copper pipes these include; the soft pipes and the hard pipes. Soft PVC coated copper pipes are flexible, easily bendable so they are suitable for the use as gas and refrigerant lines. Meanwhile the Hard PVC-coated copper pipes, offer the pipes and rigid characteristic required for structural support in water supply lines and other plumbing fixture installations where it is needed.

Soft PVC Coated Copper Pipe in Qatar

PVC-coated copper pipes are very flexible, with soft PVC cover, this makes them ideal for use in applications that involve bending, for example, gas and refrigerant lines. The PVC layer gives it the extra shield against corrosion and wear to give it a longer useful run. This kind of piping proves to be quite effective in performance as well as it is suitable for both; the residential and the commercial buildings.

Hard PVC Coated Copper Pipe in Qatar

The most common hoops of pipes are hard PVC-coated copper pipes in Qatar, which proves very rigid and strong and highly effective in water supply lines and other essential plumbing works. It withstands corrosion and physical harms hence the need to coat the copper insulation with a PVC material. These pipes are among those recommended for infrastructural developments that call for strong and durable pipes.

Benefits and Properties of PVC Copper Pipes in Qatar

Opportunities and Strengths of PVC Copper Pipes in the State of Qatar

- Durability : This is because the center metal is copper and is very rigid and has a longer life than mild steel hence the pipes will not break or wear easily.

- Corrosion Resistance : By the very nature of Copper, the pipes will be unable to corrode and therefore are not vulnerable to humidity and the salt air and for addition a UV resistant PVC covering has been provided.

- Thermal Conductivity : The thermal conductivity character of copper is considerable; therefore, copper is an excellent conductor of heat and applied in hot water systems.

- Protection Against External Factors : PVC provides protection to its environment since it forms a face as from the coating that cannot be in any way be condensed or undergo mechanical damage.

- Versatility : The type of pipes used in this engineering can be categorized as soft and hard; the smooth one can be bent to shape, good for curves, while the hard ones give more solidity, good for setting up.

- Energy Efficiency : It is also observed that such a method that use PVC coated articles reduce the energy loss to the facilities and limits thermal transfer to increases system efficiency.

- Maintenance-Free : Copper and PVC as a result they act as a very low maintenance material, and consequently therefore, the pipes generally do not feel the need to be repaired or replaced frequently.

Tel : +91 83697 23069

Email : sales1@manibhadrafittings.com

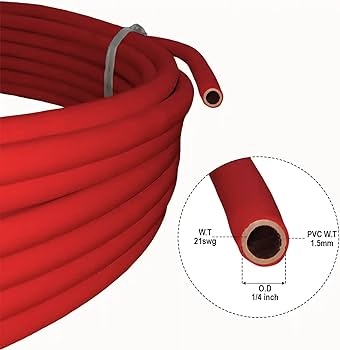

PVC Coated Copper Pipes Specification, Sizes, Grades:

PVC coated copper pipes can be bought according to the desired specifications, sizes and grades for the intended use. These pipes are available in pipe sizes of 1/4 inches to 4 inches and in both soft and hard grades based on the requirements of the application and are manufactured according to performance standards on matters such as the pipe’s hardness, flexibility, and corrosion resistance.

| Standards | EN13348/ BS EN 1057 |

| Size | 6mm to 108 mm |

| Length | 3 meter |

| Tensile Strength | 220 MPA |

| P.V.C Thickness | 0.014”to 0.059” |

| Material | Copper |

| Application | Gas Handling |

PVC Coated Copper Pipes Weight Chart in Qatar

Here is a PVC Coated Copper Pipes Weight Chart specifically for Qatar. The weight of PVC coated copper pipes is calculated mainly in terms of outer diameter (OD) of the pipe, wall thickness, and the weight of the coating. Below is a chart that depicts an approximate weight per unit length of common sizes of PVC coated copper pipes.

| Type | Size d2 t2/ d1 t1 | O.D. of the tube d1/d2/d3 | Thickness of Insulator t1/t2/t3/t4 | Length | Material | Weight Pounds/feet |

|---|---|---|---|---|---|---|

| P2320 | 1/4-0.032 3/8-0.032 | 1.02-0.87-1.89 | 0.35-0.2 | 30ft ~100ft | 0 | 0.233 |

| P2330 | 1/4–0.032 1/2–0.032 | 1.30-0.87-2.17 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.286 |

| P2420 | 1/4-0.032 3/8-0.039 | 1.42-0.87-2.29 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.39 |

| P2520 | 1/4–0.032 5/8–0.032 | 1.42-1.02-2.44 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.44 |

| P3620 | 3/8–0.0329 3/4–0.039 | 1.54-1.02-2.56 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.569 |

| P4620 | 1/2–0.032 3/4-0.039 | 1.54 1.30 2.84 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.629 |

Quick Link

PVC Coated Copper Pipes Physical Property in Qatar

PVC-coated copper pipes are engineered to combine the inherent strength and durability of copper with the protective benefits of a PVC coating. This results in pipes that have high resistance to corrosion, abrasion, and heat, and are suitable for applications in the challenging environmental conditions of Qatar.

Standard | Copper No. | Chemical Composition | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| CU% | P% | Temper | Tensile strength (MPA) | Elongation(%) | Average Grain Size (mm) | ||

| ASTM B280/68 | C12200 | 99.9 | 0.015 to 0.040 | >60 | >205 | >40 | >0.040 |

| >50 | >245 | ||||||

Mechanical Property Of PVC Coated Copper Pipes

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

PVC Coated Copper Pipes Chemical Composition

| Copper Pipe (Incl. Silver) | 99.85% Min. |

| Phosphorus | 0.013 to 0.5% |

| Total Impurities | 0.06% Max. |

Uses of PVC Coated Copper Pipes

Industrial Applications:

- Gas Lines: The industry that makes use of copper flexible soft PVC coated tubes includes gases transportation in different industries.

- Refrigeration Systems: Refrigeration and AC application the soft PVC-coated pipes of the sort that assist in the circulation of refrigerants.

- Water Supply Systems: The supply of high pressure water in factories and plants can be done with hard flexible PVC-Coated pipe line.

- Hydraulic Systems: Hydraulic machinery and equipment require hard PVC coated Pipes; they are somewhat hard.

Normal Applications:

- Residential Plumbing: The common plumbing pipes that are installed in homes include; Copper pipes covered with hard PVC for water supply.

- Heating Systems: PVC coated pipes – both, soft and hard are used for the residential heating installations including under-floor heating.

- HVAC Systems: In home AC flexible soft pipes made from PVC material with chlorinated coating are used to enhance the means of air and fluid conveying.

- Landscaping: In the compounds, homes and in landscaping, flexible soft PVC-coated pipes are well applied in the following ways.