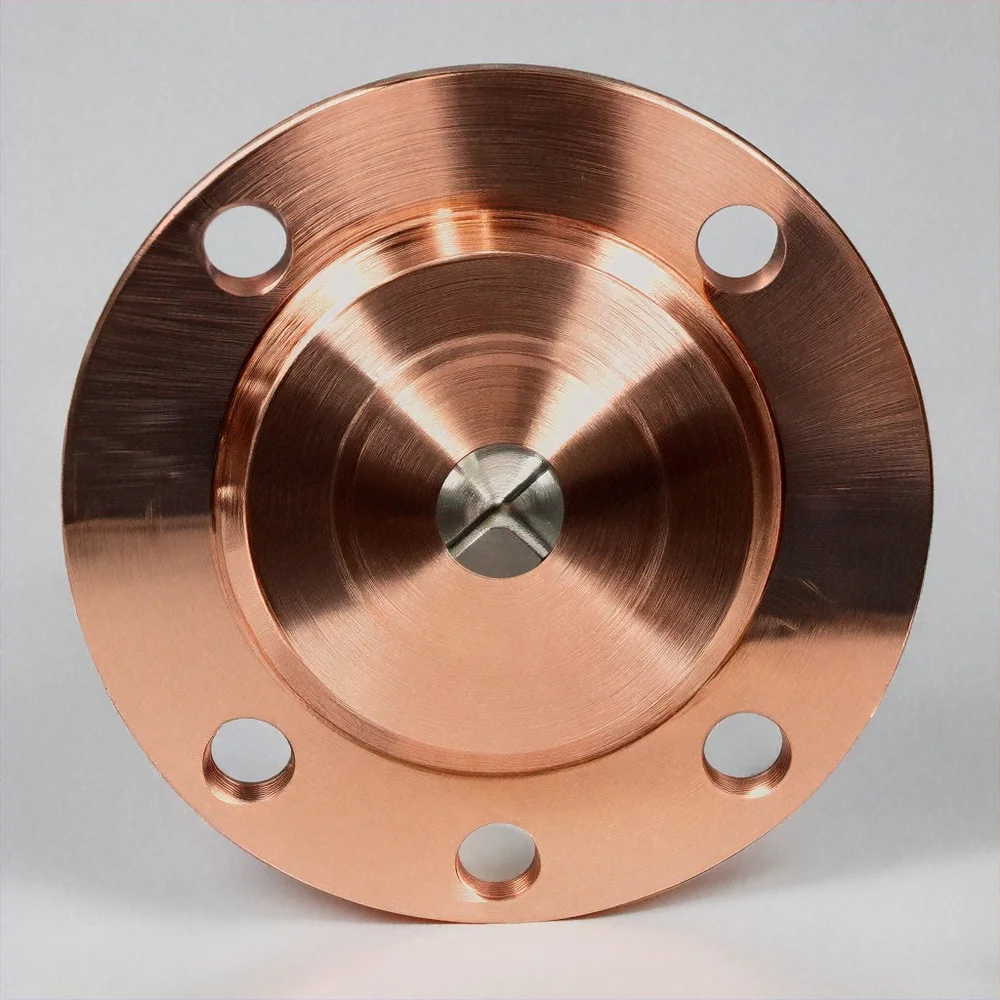

Manibhadra Copper Fitting Manufacturer is engaged in serving the industrial sector of Qatar with the best quality copper flanges. Being highly resistant to corrosion and being very durable and accurately engineered these flanges are crucial in any system that demands strong and reliable joints. The company strongly positioned in the market takes ever-y measure to guarantee that a particular product of its fleet meets international standards. Copper flanges are fit for use in oil and gas industries, plumbing, as well as applications in HVAC systems, proving their cost-effectiveness within facilities in Qatar.

Copper Flanges Manufacturer, Stockist, and Exporter in Qatar : Types

Copper flanges are available in many types each being intended for distinct operations on a system. Starting with the weld-neck flanges for improved pressure tolerance and ending with the slip-on flanges for easier operation, each offers its advantages. It is true that these flanges are necessary in various sectors including energy, construction and manufacturing through out various applications.

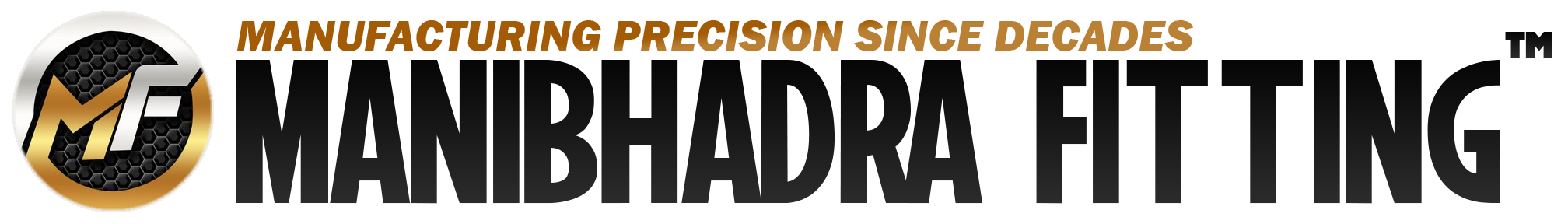

Copper Weld Neck Flanges in Qatar

The compelling weld neck flange is characterized by a long tapered hub ensured to enhance the stress range at one edge. It is normally recommended for lubricant manufacturing industries, oil refineries, and production plants in Qatar due to the high-end robust construction and conformity to pressure and safe performance.

Copper Slip-On Flanges in Qatar

Widely used for their Quick Installation, slip-on flanges are mounted over the pipe and then welded to it. Most of these flanges are available in the plumbing and HVAC systems industries due to their robust connections and durability with little need for maintenance.

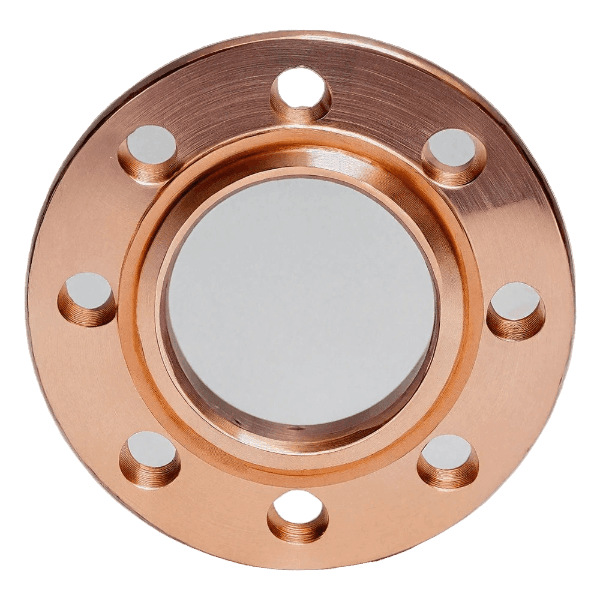

Copper Threaded Flanges in Qatar

Threaded flanges are ideal for use in areas where its impossible to weld the flanges are screwed directly on the pipes. These flanges are normal on small piping and temporary pipelines and provides leak-proof joints to the systems used.

Copper Socket-Weld Flanges in Qatar

These flanges are intended for piping with small diameter to offer high pressure resistance. The pipe is inserted into a socket so that there are tight fittings making the connection hard to dismantle. They are suitable for applications in compressed air systems as well as hydraulic pipeline systems.

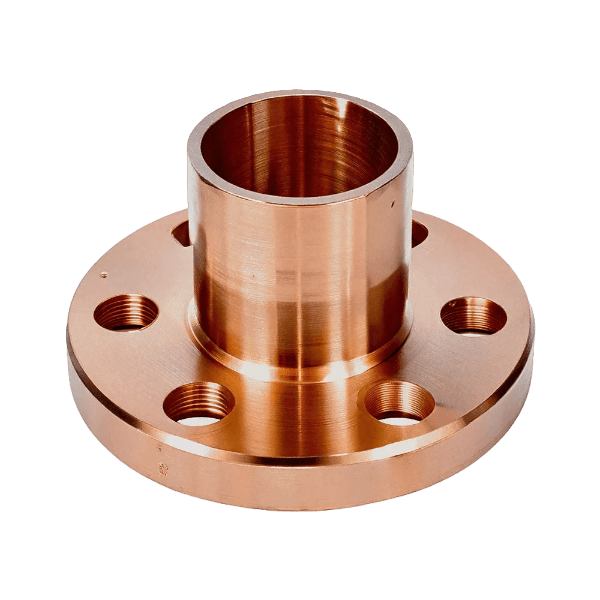

Copper Blind Flanges in Qatar

If applied, blindness flanges close pipe ends in order to guarantee safety of the system, as well as its structural reliability. They are useful particularly in production sectors such as the oil and gas where it is crucial to have isolation for system services or overhaul without anymore leakage.

Copper Orifice Flanges in Qatar

These are used for flow measurement and pressure control in pipelines The above flanges are the specialized flanges. They are necessary in accurate works including chemical plant industries and water treatment facilities.

Copper Flanges in Qatar : Properties

Copper flanges exhibit a tremendous mechanical strength all in all, which happens to be ideal for a variety of applications in Qatar. These assets such as Thermal conductivity, corrosion resistance and the mechanical strength are key in operations that cannot overemphasize reliability. Those characteristics make the performance permanent and reduce the level of maintaining, even if the conditions for using are severe.

- High Corrosion Resistance : Copper flanges can easily resist high levels of corrosion through exposure to salts and chemicals for use in marine and industrial systems.

- Superior Thermal Conductivity : Best suited for heat exchange operations, copper flanges facilitate temperature control effectively; thereby, widely used in the HVAC systems and thermal power stations.

- Excellent Durability : The mechanical strength of copper means that these flanges are foolproof when under pressure and at elevated temperatures to prevent system failures.

- Flexibility in Design : Copper flanges are produced in different forms and can thus be fitted in systems that require them in various capacities or in different sized systems.

- Leak-Proof Connections : Manufactured to optimized standard to ensure that they create close tolerance, these flanges eliminate leakage from equipment, making them ideal for use in safety-oriented processes.

- Environmentally Friendly : Copper is a renewable material and it is recyclable these flanges embody environmental conservation in any organization that aspires to stand as environmentally friendly.

Copper Flanges Specification Table

Copper flanges are produced to fulfill various industry requirement, and provide flexibility in terms of their specification, size, and grade. These flanges are designed carefully to provide better suitability, mechanical properties and reliability in nearly all applications.

| Parameter / Property | Details |

|---|---|

| Material | Copper, Copper Alloys (C11000, C12200, etc.) |

| Size Range | ½ inch to 24 inches (Custom sizes available) |

| Type | Slip-On, Weld Neck, Blind, Threaded, Lap Joint, etc. |

| Standard | ASME B16.5, ASTM B62/B152, EN 1092, DIN, etc. |

| Pressure Rating | Class 150, Class 300, Class 600, and higher |

| Temperature Range | Up to 400°F (204°C) (Varies based on alloy) |

| Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Material Composition | 99.9% Pure Copper (C11000) or Copper Alloys (C12200) |

| Tensile Strength | 210-250 MPa (Varies by grade and alloy) |

| Yield Strength | 33-70 MPa (Varies by grade and alloy) |

| Density | 8.94 g/cm³ |

| Thermal Conductivity | 390-400 W/m·K |

| Electrical Conductivity | 97-101% IACS |

| Corrosion Resistance | Excellent resistance to water, steam, and mild acids |

| Ductility | Highly ductile, easy to form and fabricate |

| Weldability | Excellent weldability with standard methods |

| Finish | Smooth, Serrated, or Custom as per requirement |

| Applications | Plumbing, HVAC, Medical Gas Systems, Industrial Piping |

| Customization | Available in sizes, coatings, and special designs |

Tel : +91 83697 23069

Email : sales1@manibhadrafittings.com

Copper Flanges Manufacturer, Stockist and Supplier in Qatar :- Size, Weight, and Dimensions Table

Copper flanges come in different sizes, weight and dimensions in order to meet the many demand in the market. It is thus versatile enough to fit every standard and custom needs as it provide solution for oil and gas industry, plumbing, and HVAC systems. One would not doubt that the presence of options ensures compatibility into different systems of piping.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Copper Flanges Manufacturer, Stockist and Supplier in Qatar :- Applications

Copper flanges are necessary for the industrial and general sector in Qatar, those are used to connect and join pipe systems. They are used at high pressures and are resistant to corrosion therefore they can be applied in institutions such as the oil and gas, construction and utilities.

Industrial Applications in Qatar :

Copper flanges are a common feature in various industries in Qatar, such as HVAC, plumbing, oil and gas, and desalination plants, owing to their exceptional corrosion resistance and sustained strength.

- Oil and Gas Pipelines : Provides safe and watertight joints in high pressure systems.

- Chemical Processing Plants : Resists eroding material and high heat conditions.

- HVAC Systems : Provides the ability to transfer heat successfully and to initialize the stability of the systems required.

- Thermal Power Plants : Controls expansion in high-temperature applications.

- Water Treatment Facilities : Offers rugged and non-corrodible connections in applications of fluid control.

General Applications in Qatar :

- Residential Plumbing : Paves way to safe and reliable water connectivity.

- Marine Applications : Resistance to corrosive atmospheres such as environments with high salinity.

- Fire Protection Systems : Improves production reliability when the working conditions are high pressure.

- Hydraulic Systems : Affords sealed connection points for smooth and constructive fluid coupling.

- Compressed Air Systems : Able to create leak-free connections required for efficient running.

Copper Flanges Manufacturer, Stockist and Supplier in Qatar :- Advantages

Copper flanges are extraordinary because they excel in numerous uses, providing inflexibility and long-lasting sturdiness.

- Corrosion Resistance : Cuts costs while delivering a long-lasting performance in difficult working conditions.

- Ease of Installation : Reduces setup costs by palliating labor and time associated expenses.

- High Strength : Withstands torques and operating temperatures in position.

- Thermal Efficiency : Reduces heat transfer rate in flow systems.

- Customizable Options : Flexible for use on Industrial and general uses.

- Sustainability : Optimal from the environmental perspective and can be recycled, thereby supporting green causes.

Quick Link