Manibhadra Copper Fitting Manufacturer is one of the leading manufacturer as well as stockiest and exporter of extensive assortment of copper flanges offered in Doha. Our copper flanges are best known to be of excellent quality, flexibility and also very durable. We provide for application in multiple sectors of the economy which allows us to supply products with high performance and durability. Since we have been operating in the market and paying special attention to our customers, we have created a brand image for ourselves in the market.

Copper Flanges Manufacturer, Stockist, and Exporter in Doha : Types

There are several types of copper flanges offered by us and these flanges are best suited for different applications. It ranges from weld neck flanges to our orifice flanges, which when used guarantee efficiency in a number of industrial and general applications. In a nutshell, our flanges are uniquely designed to offer strength, durability and ease of installation which fits most purposes.

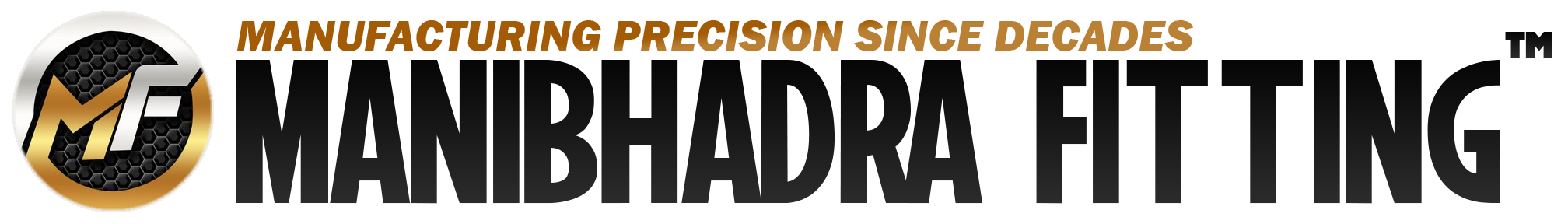

Copper Weld Neck Flanges in Doha

Copper weld neck flanges are ideal where high pressure is involved because of the weld neck design. The external geometry of these flanges comprises of a long tapered region known as the hub that further strengthens the connection. They are often applied in pipelines with the help of which the welded neck will provide a strong and tight connection.

Copper Slip-On Flanges in Doha

It is easy to install, slip-on flanges are cheaper and ideal for low pressure applications. These flanges fit over the pipe and then are attached by welding, thus they are appropriate for use in systems that will often be unbolted. They can be seen in water treatment station, plumbing, heating and ventilating systems to name but a few.

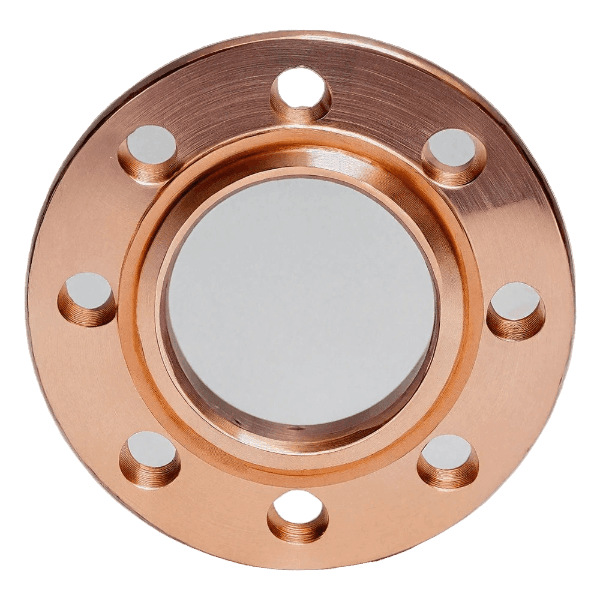

Copper Threaded Flanges in Doha

Threaded flanges are mainly used for those applications in which joining by welding is not possible. These flanges contain internal thread that can be screwed on the pipe hence giving it a strong nut like connection. These types are mostly applied in pipes and systems of small diameters with frequent requirement for assembling and dissembling.

Copper Socket-Weld Flanges in Doha

Socket weld flanges are typically arranged in small diameter piping systems to handle high pressure systems. These flanges have a recess in them into which the pipe is fitted and welded thus offering better security of the joint from leakage. There are applications in chemical processing as well as in operation of hydraulic systems.

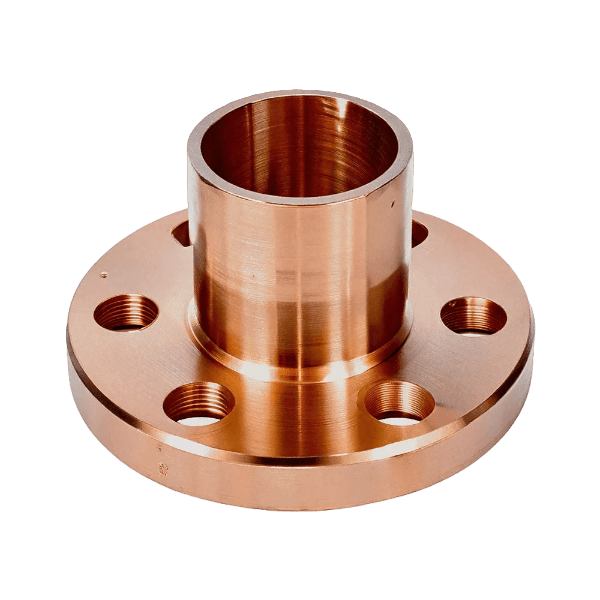

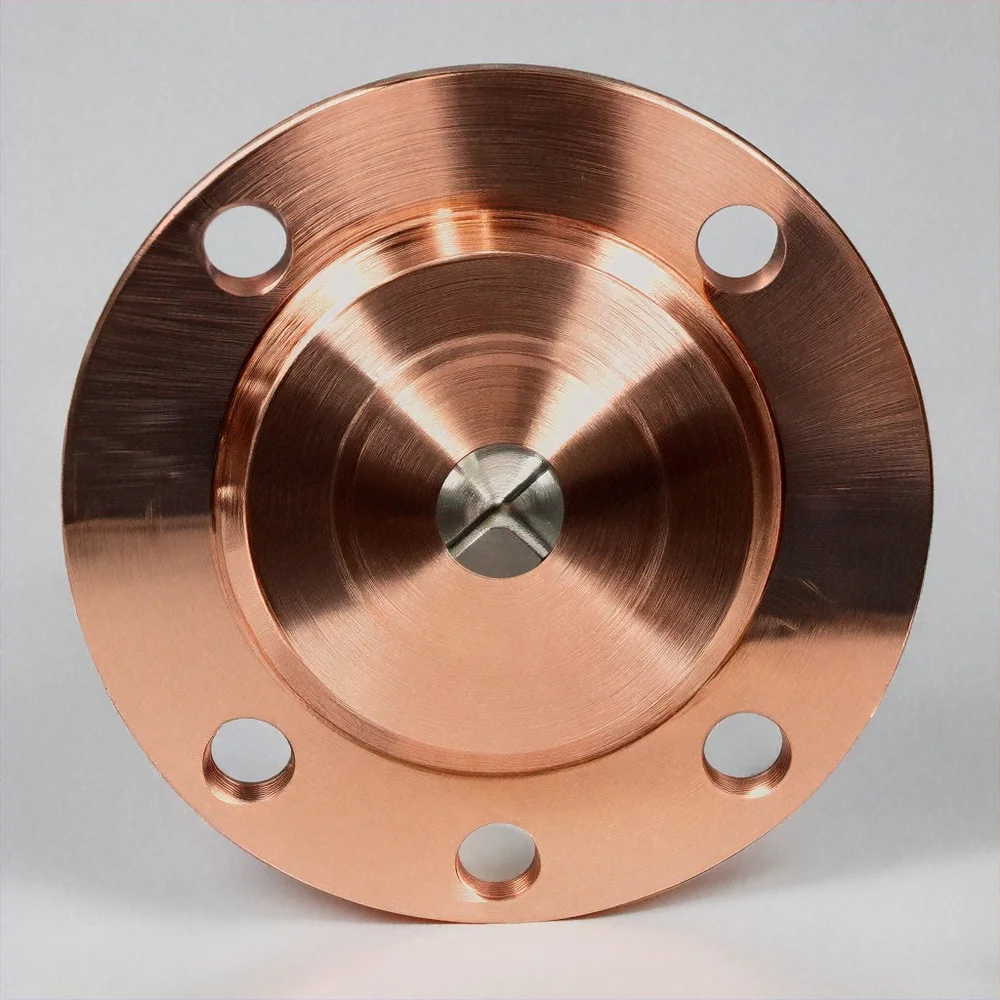

Copper Blind Flanges in Doha

Blind flanges are applied to shutdown the ends of pipes, valves, and pressure vessels as well as cover openings. It gives a competent seal and is suitable for systems that undertake routine examinations and service. Blind flanges are used extensively in the oil and gas industry and petrochemical applications, as well as in the water treatment field.

Copper Orifice Flanges in Doha

Orifice flanges being used jointly with orifice plates with the aim to control the flow rate of liquids and gases. These flanges give accurate measure of the flow rates and are widely used in process control and instrumentation.

Copper Flanges in Doha : Properties

Copper flanges are prized for their great characteristics, and therefore can be useful for several purposes in both industrial and general use within the city of Doha. Such properties consist of high and localized corrosion resistance, conductivity of temperature and electricity, and high mechanical strength. Copper flanges are characterized by specific properties that guarantee long durability and stable work from various conditions.

- Corrosion Resistance : Copper flanges have the ability to resist corrosion better than many materials hence they are acceptable where the surrounding environment is hostile and where chemical abrasion is likely to occur. This property allows for long term longevity and low maintenance requirements of this property.

- Thermal Conductivity : The heat transfer property opinion of Copper makes it useful where heat transfer is critical. Copper flanges are used in all the HVAC systems, heat exchanging apparatus and various industrial process where a heat sink is required.

- Electrical Conductivity : Because of its better electrical conductivity than other materials, copper flanges are suitable for electrical and electronics applications. They have wide uses in grounding systems, electrical fittings, power transmission equipment etc.

- Mechanical Strength : Copper flanges are mechanically very strong so that they are capable of delivering good results where pressure and temperature are high. This characteristic make them suitable for used in pipelines, pressure vessels and other necessary applications.

- Flexibility : The ease of fabrication and installation of copper flanges can therefore be attributed to its characteristic such as malleability and ductility. It also makes for a good fit that does not allow for seepage and makes the whole system very reliable.

- Aesthetic Appeal : Copper flanges have a unique finishing where they produce them and therefore are appropriate in architectural and decorative industries. Some people prefer copper fittings because of the appearance that comes as a result of rusting or oxidation of the copper metal.

Copper Flanges Specification Table

Copper flanges are manufactured in different specifications, sizes and grades, so that they can be used to meet the needs of a particular organization. This way, a very wide field of application is guaranteed so that we can offer the ideal solution for every application from simple local heating systems to large industrial facilities.

| Parameter / Property | Details |

|---|---|

| Material | Copper, Copper Alloys (C11000, C12200, etc.) |

| Size Range | ½ inch to 24 inches (Custom sizes available) |

| Type | Slip-On, Weld Neck, Blind, Threaded, Lap Joint, etc. |

| Standard | ASME B16.5, ASTM B62/B152, EN 1092, DIN, etc. |

| Pressure Rating | Class 150, Class 300, Class 600, and higher |

| Temperature Range | Up to 400°F (204°C) (Varies based on alloy) |

| Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Material Composition | 99.9% Pure Copper (C11000) or Copper Alloys (C12200) |

| Tensile Strength | 210-250 MPa (Varies by grade and alloy) |

| Yield Strength | 33-70 MPa (Varies by grade and alloy) |

| Density | 8.94 g/cm³ |

| Thermal Conductivity | 390-400 W/m·K |

| Electrical Conductivity | 97-101% IACS |

| Corrosion Resistance | Excellent resistance to water, steam, and mild acids |

| Ductility | Highly ductile, easy to form and fabricate |

| Weldability | Excellent weldability with standard methods |

| Finish | Smooth, Serrated, or Custom as per requirement |

| Applications | Plumbing, HVAC, Medical Gas Systems, Industrial Piping |

| Customization | Available in sizes, coatings, and special designs |

Copper Flanges Manufacturer, Stockist and Supplier in Doha :- Size, Weight, and Dimensions Table

Standard copper flanges come in various sizes, weight and dimensions with an option for customization to meet the customer’s need. It also incorporates small-diameter pipeline possibilities and extensive industrial systems amplitude. The different sizes and weights are important because it means that our flanges can be made to order, to fit the exact requirements of each project as required, which is always advantageous.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Copper Flanges Manufacturer, Stockist and Supplier in Doha :- Applications

Copper flanges are essential being used in different fields and industries in Doha. These pipes possess outstanding characteristics that qualify them for use in plumbing, air conditioning, and heating systems and many other industrial processes. High quality and durability of copper flanges makes their relevance when it comes to performance and efficiency in various fields.

Industrial Applications in Doha :

- Oil and Gas Industry : Copper flanges are utilized in pipe systems, valves, and pressure vessel applications to ensure the structures secure and reduce leakage within oil and gas production and treatment regions.

- Chemical Processing : Because copper flanges have the ability to resist corrosion from a chemical and environmental impact, it is widely used in chemical processing plants for usage in pipelines, reactors, and heat exchangers.

- HVAC Systems : Copper flanges are normally used in HVAC systems due to their ability to conduct heat and also because of theirs high resistance to corrosion.

- Water Treatment : Copper flanges are used in water treatment plants for connections in piped systems and equipment to guarantee integrity of water supplies.

- Power Generation : Besides, due to its good electrical and thermal conductivity, copper flanges are applied in the power plants to ensure connection in the power generation and distribution.

General Applications in Doha :

- Plumbing : Copper flanges are widely utilized in plumbing of the residential and commercial buildings in order to obtain secure leak proof connection of water supply lines.

- Architectural Applications : Copper flanges are quite attractive and can therefore be used largely in decorative and architectural applications where the flanges will add beauty to the structures.

- Electrical Systems : Copper flanges are utilized to connect copper to other materials for grounding systems and electric fittings, to guarantee safety and adequacy in power installations.

- Automotive Industry : Copper flanges must be used in automobile industries in its strength, endurance and corrosion resistance so as to produce good and reliable performance in the systems in the automobiles.

- Marine Applications : Copper flanges also afford excellent corrosion properties making them suitable for marine applications which include ship, boat and offshore structures.

Copper Flanges Manufacturer, Stockist and Supplier in Doha :- Advantages

Copper flanges are advantageous in different manners that attract many users to consider its use in many areas. Approaches and dependability of different kinds of materials also make them fit proper demands of various segment.

- Durability : Copper flanges are very strong and dependable and hence they will not require frequent replacement as may be required with other flanges.

- Corrosion Resistance : Most copper flanges are made to have anticorrosive features, and this makes them have ability to work under harsh conditions and thus it will not require frequent maintenance.

- Thermal and Electrical Conductivity : The specialty of this material, copper, is that it thus has high thermal and electrical conductivity so that copper flanges are also used for heat exchange and electrical contacts.

- Mechanical Strength : Copper flanges have good mechanical properties giving them the strength they require mainly in high pressure and temperature applications.

- Flexibility : Due to the nature of metal, especially copper, being soft and easily formed copper flanges are easily fabricated and installed where they will properly seal and fit without leakage.

- Aesthetic Appeal : Due to the raw attraction of copper flanges, they are ideal for architectural and ornamental applications making installations to have an appealing appearance.