Saudi Arabia based Manibhadra Copper Fitting Manufacturer is a well known manufacturer of copper flanges to the competitive market that is always in a state of constant flux. Copper flanges that we offer are designed to cause long lasting, precise manufacturing and we use them in a number of industries. Pleased with our long-standing and reliable system networks, we offer our clients in Saudi Arabia and across the world on-time delivery and quality products. As a result of our commitment to quality, we have secured ourselves as a preferred source of supplies in the region’s industrial market.

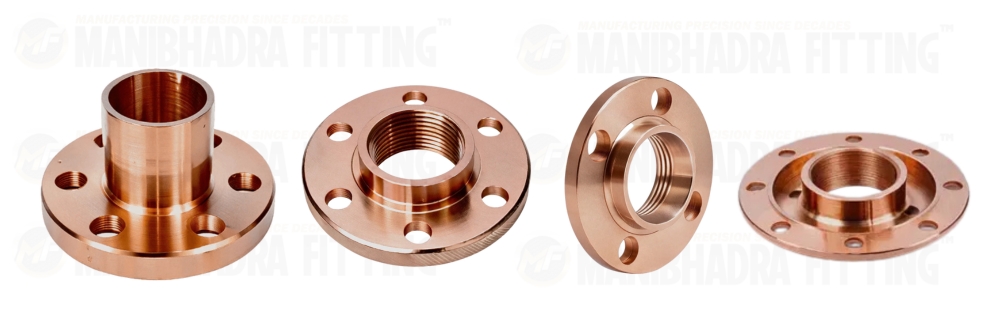

Copper Flanges Manufacturer, Stockist, and Exporter in Saudi Arabia : Types

Manibhadra Copper Fitting Manufacturer came up with a catalogue of Copper flanges depending with the various needs in the various sectors. Every kind of flange is made to precise standard that would meet the respective requirement in different operation environments.

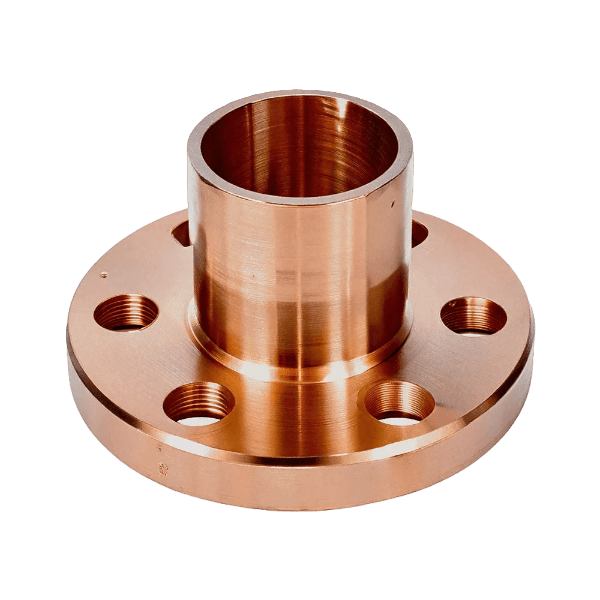

Copper Weld Neck Flanges in Saudi Arabia

These flanges are fit for pressure vessels since they are usually welding to pipe thus providing a less leakage and strong connection. They are well suited for application where accesses for inspections on regular basis may be required due to leak or pressure test.

Copper Slip-On Flanges in Saudi Arabia

These flanges are slipped over the pipe and are much suited for a lower pressure application only. They feature the best performance especially where stresses of piping in relation to an alignment system are of great concern.

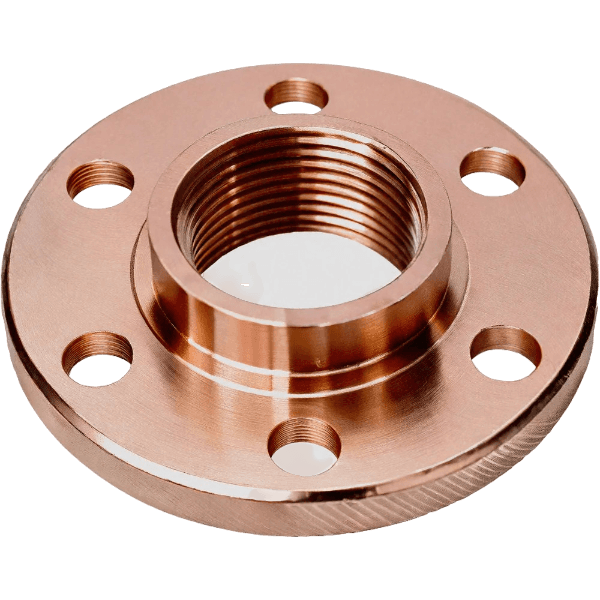

Copper Threaded Flanges in Saudi Arabia

Better for those systems where welding is impossible threaded flanges are screwed to the pipe. Though mostly designed to be used in small diameter, low pressure applications, the system is easily assembled and dismantled.

Copper Socket-Weld Flanges in Saudi Arabia

These are applicable on smaller pipes and in high pressure condition. The pipe is fed into socket end of the pipe then welded, this produces less rough surface hence a better flow characteristics.

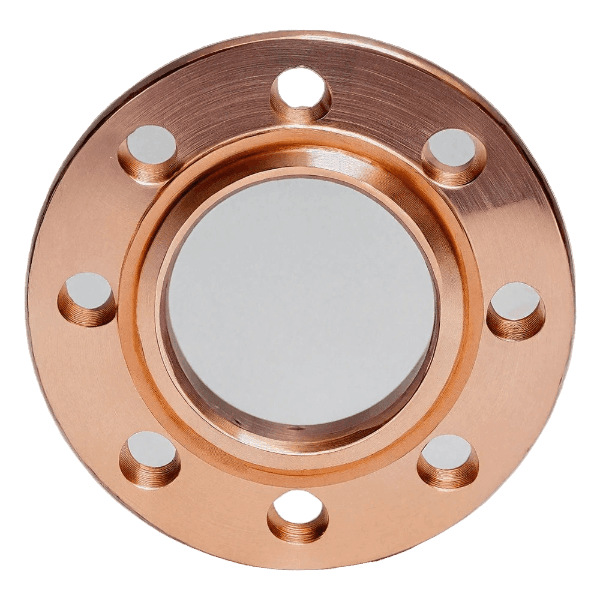

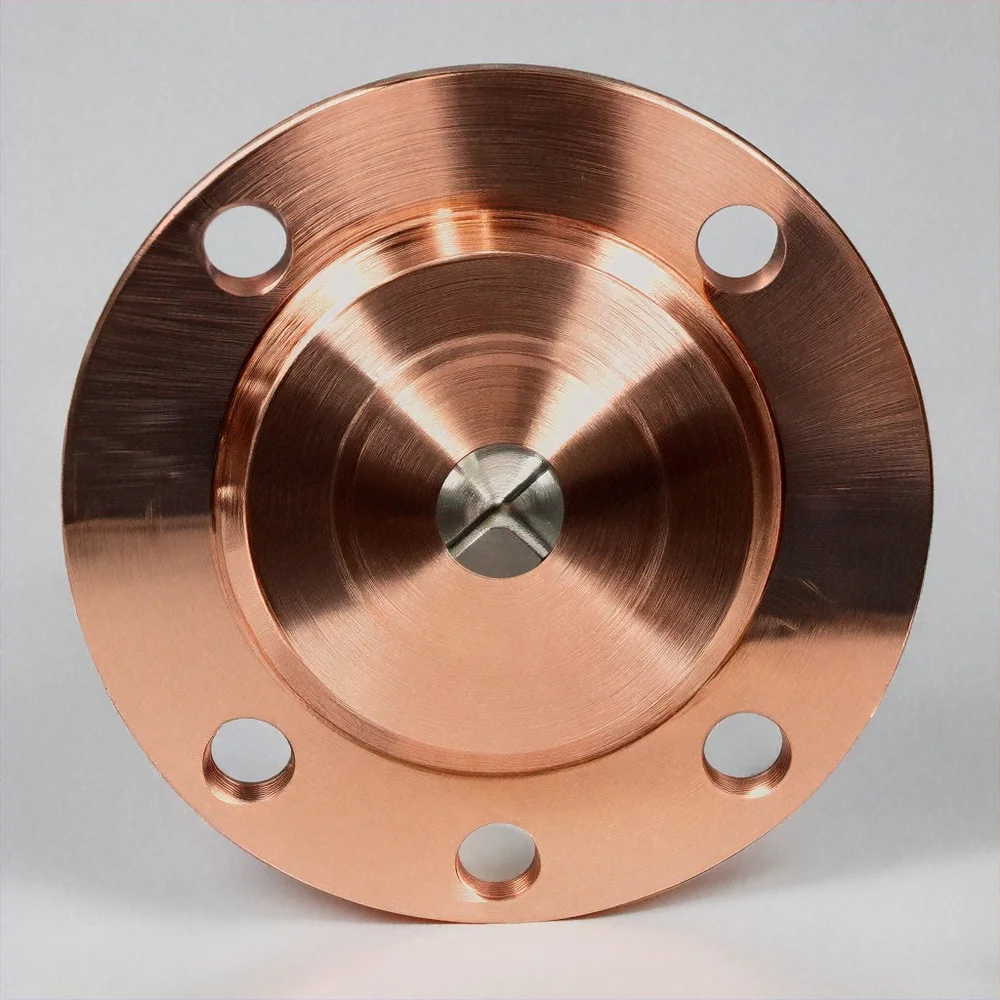

Copper Blind Flanges in Saudi Arabia

Being utilized to shut off the ends of piping systems, these flanges are crucial to maintenance and repair. They are mainly used in high pressure systems and are intended to block fluid passage through a pipeline.

Copper Orifice Flanges in Saudi Arabia

They are utilized together with the orifice meters to measure the rate of flow of fluids.. It is desirable they operate under high pressure conditions, since they are critical in applications involving flow measurement in many industrial processes.

Copper Flanges in Saudi Arabia : Properties

Copper flanges from Manibhadra Copper Fitting Manufacturer hold very good mechanical properties hence useful for the strenuous conditions of Saudi Arabia industries. These properties guarantee a long-life cycle and stability of the product as well as reliability under extreme conditions.

- Durability : Copper flanges are generally noted for their fine capability towards abrasion and hence they can serve in areas where pressure is likely to be applied together with high temperatures.

- Corrosion Resistance : Inherent corrosion resistance of copper guarantees that such flanges will not deteriorate, both in terms of structure and appearance, when in contact with aggressive chemicals.

- Thermal Conductivity : These copper flanges show heat transfer characteristics due to its ability of high thermal conduction which is important in heat exchange procedures in industries.

- Flexibility : Copper flanges are very ASIC in design and application flexibility since they can be easily engraved to meet a specific project designs.

- Ease of Installation : These flanges are produced accurately to allow easy and fast fixing, which results to decreased down time and improved productivity.

- Cost-Effectiveness : However, cost aspects point towards copper flanges: they are cheaper to use although they have both strength and heat conductivity advantages over other flanges.

Copper Flanges Specification Table

Manibhadra Copper Fitting Manufacturer offers copper flanges in different size, grade, and specifications which can fulfill the requirement of Saudi Arabia. Our product line features both stock and modular items so as to fit various piping systems.

| Parameter / Property | Details |

|---|---|

| Material | Copper, Copper Alloys (C11000, C12200, etc.) |

| Size Range | ½ inch to 24 inches (Custom sizes available) |

| Type | Slip-On, Weld Neck, Blind, Threaded, Lap Joint, etc. |

| Standard | ASME B16.5, ASTM B62/B152, EN 1092, DIN, etc. |

| Pressure Rating | Class 150, Class 300, Class 600, and higher |

| Temperature Range | Up to 400°F (204°C) (Varies based on alloy) |

| Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Material Composition | 99.9% Pure Copper (C11000) or Copper Alloys (C12200) |

| Tensile Strength | 210-250 MPa (Varies by grade and alloy) |

| Yield Strength | 33-70 MPa (Varies by grade and alloy) |

| Density | 8.94 g/cm³ |

| Thermal Conductivity | 390-400 W/m·K |

| Electrical Conductivity | 97-101% IACS |

| Corrosion Resistance | Excellent resistance to water, steam, and mild acids |

| Ductility | Highly ductile, easy to form and fabricate |

| Weldability | Excellent weldability with standard methods |

| Finish | Smooth, Serrated, or Custom as per requirement |

| Applications | Plumbing, HVAC, Medical Gas Systems, Industrial Piping |

| Customization | Available in sizes, coatings, and special designs |

Copper Flanges Manufacturer, Stockist and Supplier in Saudi Arabia :- Size, Weight, and Dimensions Table

All our copper flanges are standard and we supply them in different sizes, weight, and dimension to suit the various industries. The various sizes enable our products to interface smoothly with other systems, and because of the vast variety of weights and dimensions there is no problem accommodating pressure and flow. This flexibility plays a great role in enhancing the performance and satisfactory levels that the piping systems in which they are installed are capable of delivering.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Copper Flanges Manufacturer, Stockist and Supplier in Saudi Arabia :- Applications

Copper flanges are standard components of many industries and everyday uses in Saudi Arabia as they act as vital connections across pipe systems. Their usefulness cannot be overemphasized, especially in extreme pressure applications, and mundane general applications.

Industrial Applications in Saudi Arabia :

- Oil and Gas Industry : As adopted in the works related to the construction and subsequent overhaul of pipelines, the formation of leak-tight connections during compression.

- Chemical Processing : Chemically durable since most of them do not corrode when coming into contact with different chemicals.

- Power Generation : Criminally significant in cooling systems and heat exchangers which are responsible for providing the right heat control.

- Marine Engineering : Applied in vessels and offshore platforms construction as seawater corrosion is not detrimental to the product.

- HVAC Systems : Crucial in applications such as; heating, ventilation, and air conditioning due to its construction that allows efficient management of the fluid.

General Applications in Saudi Arabia :

- Plumbing Systems : Applied in residential and commercial water systems to attain lasting watertight joints.

- Water Supply Networks : Guarantees secure links in municipal water supply networks and water distribution network.

- Firefighting Systems : Transmits strong signals in the firefighting systems to warrant optimal functional performance.

- Automotive Industry : Heavy users of the metal in automotive industries with specific reference to purification of exhausts and forging of various auto parts.

- Construction : Crucial in various construction functions like the fixating of the heating and cooling.

Copper Flanges Manufacturer, Stockist and Supplier in Saudi Arabia :- Advantages

Copper flanges from Manibhadra Copper Fitting Manufacturer come with certain benefits that advance the product’s suitability for use in Saudi Arabia. Here are some key benefits.

- Long Service Life : The copper flanges is commonly associated with long service life and a weak demand for maintenance, hence they have low operational cost.

- High Strength : They are more mechanically stronger than other makes and can be used in pressure vessels.

- Thermal Efficiency : Low thermal resistance enables effective heat transfer a quality that is essential for use in thermal management systems.

- Corrosion Resistance : High rated corrosion resistance gives guarantee for longevity and efficiency in extreme conditions.

- Versatility : It has different dimensions and can be fabricated to serve various projects depending on its requirements.

- Environmental Sustainability : Copper is a more recyclable material and, hence, these flanges are environment friendly.