Mobile: +91 8369723069 | Email: sales1@manibhadrafittings.com

PVC Coated Copper Pipe Manufacturer, Dealer, Exporter in Maldives – Manibhadra Fittings

Manibhadra Copper Fitting Manufacturer is among the most trusted suppliers of PVC Coated Copper Pipes in the Maldives due to a family of specialized services. We produce pipes that are strong, flexible, and can readily withstand unfavorable environmental situation which make them suitable for the island nation. Thanks to a dominant position on the Maldivian market, our company is aimed at providing top-quality products to meet the needs of industrial production, housing construction, and environmentally friendly infrastructure projects.

Types of PVC Coated Copper Pipes in Maldives

Manibhadra Copper Fitting Manufacturer provide an assortment of services of PVC Coated Copper Pipes for particular industrial and residential demand in Maldives. The product variations provided make it possible to achieve high performance in more demanding applications, which demand high protection and durability.

Soft PVC Coated Copper Pipes in Maldives

Intended for the situations when pipes need to be easily movable and adjusted, these pipes are used on the majority of HVAC and refrigeration systems. The soft PVC coating has the ability to offer corrosion as well as resistances again salt laden air making them ideal for coastal application like the Maldives.

Hard PVC Coated Copper Pipes in Maldives

These pipes provide improved stiffness and are suitable for permanent use in these industries such as in the oil and gas ones in the construction of pipeline. The rigid PVC layer offers high wear and impact durability besides acting as a protective shield against common forms of wear and tear.

Properties PVC Coated Copper Pipe in Maldives

These properties have been designed in our PVC Coated Copper Pipes to provide excellent performance for the harsh environment of the Maldives. Such properties make the pipes useful for extensive use in industrial and residential practices among others.

- Corrosion Resistance : Originally, the PVC layer safeguards the polyethylene core from corrosion originating from the humid and saline conditions of the Maldives – improving the pipes’ durability.

- Flexibility : Flexible pipes coated with soft PVC are easy to fit into complex HVAC and plumbing systems therefore decreasing installation costs.

- High Mechanical Strength : The pipes that are constructed with a hard PVC coated layer provide better mechanical substantially that enables them to withstand pressure in some industrial applications such as oil and gaseous.

- Thermal Resistance : The PVC coating material also acts as an insulating material therefore contributes to heat conservation and energy preservation in HVAC and refrigeration industries.

- UV Resistance : Pipes we produce are resistant to the affects of long time exposure to sunlight, thereby fit for use in array of solar energy application systems.

- Chemical Resistance : The PVC that forms the outer skin of the pipe provides a shield against chemical actions on the copper pipe so making the pipe suitable for use in chemical and gaseous industries.

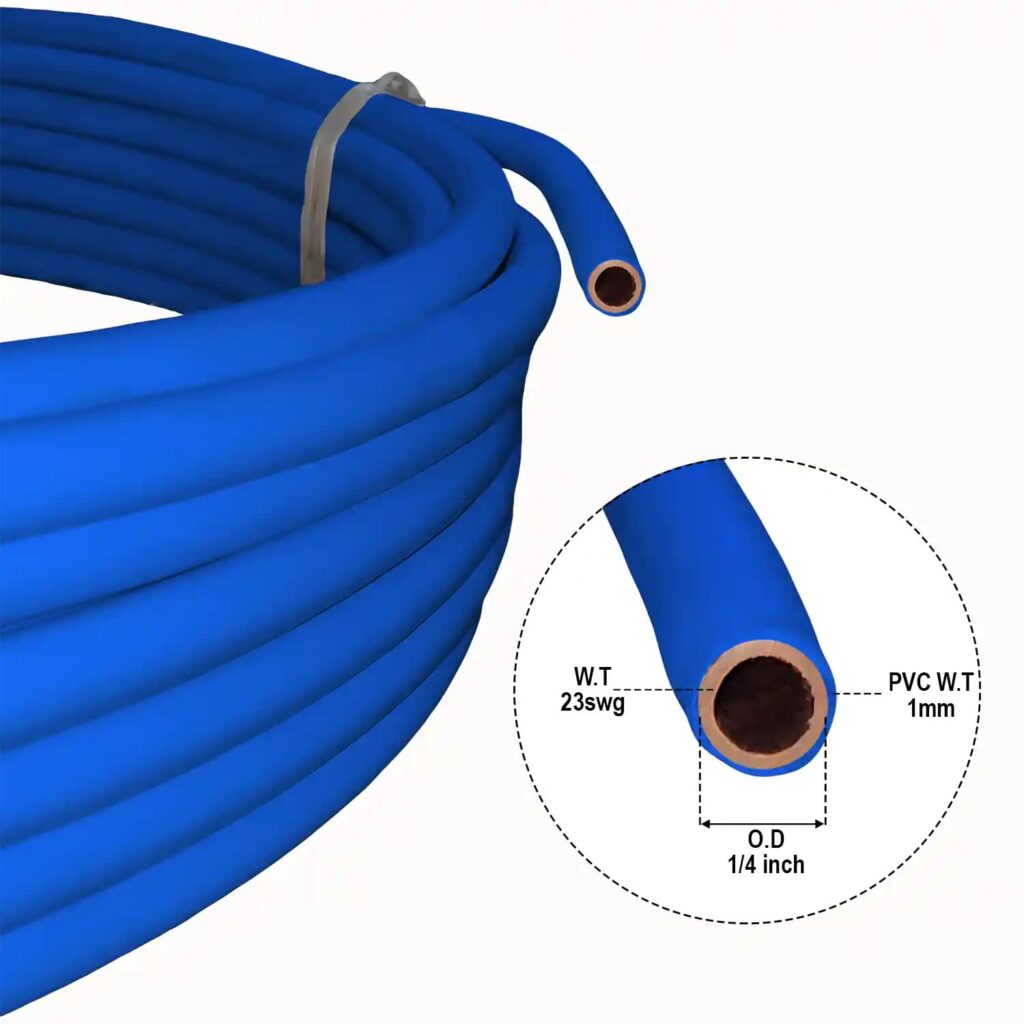

PVC Coated Copper Pipe Size, Weight, and Dimensions

At Manibhadra Copper Fitting Manufacturer, different products that we present include PVC Coated Copper Pipes which in terms of size, weight, and dimensions come in different sizes for the Maldivian market. Our vast catalogue makes it easy for our equipment to integrate with different systems across residential buildings , factories and plants among others. The fact that the dimension can vary brings versatility and provides a smooth incorporation into the already existing structure.

| Standards | EN13348/ BS EN 1057 |

| Size | 6mm to 108 mm |

| Length | 3 meter |

| Tensile Strength | 220 MPA |

| P.V.C Thickness | 0.014”to 0.059” |

| Material | Copper |

| Application | Gas Handling |

Tel: +91 83697 23069

Email : sales1@manibhadrafittings.com

PVC Coated Copper Pipes Weight Chart in Maldives

| Type | Size d2 t2/ d1 t1 | O.D. of the tube d1/d2/d3 | Thickness of Insulator t1/t2/t3/t4 | Length | Material | Weight Pounds/feet |

|---|---|---|---|---|---|---|

| P2320 | 1/4-0.032 3/8-0.032 | 1.02-0.87-1.89 | 0.35-0.2 | 30ft ~100ft | 0 | 0.233 |

| P2330 | 1/4–0.032 1/2–0.032 | 1.30-0.87-2.17 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.286 |

| P2420 | 1/4-0.032 3/8-0.039 | 1.42-0.87-2.29 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.39 |

| P2520 | 1/4–0.032 5/8–0.032 | 1.42-1.02-2.44 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.44 |

| P3620 | 3/8–0.0329 3/4–0.039 | 1.54-1.02-2.56 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.569 |

| P4620 | 1/2–0.032 3/4-0.039 | 1.54 1.30 2.84 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.629 |

PVC Coated Copper Pipes Physical Property

Standard | Copper No. | Chemical Composition | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| CU% | P% | Temper | Tensile strength (MPA) | Elongation(%) | Average Grain Size (mm) | ||

| ASTM B280/68 | C12200 | 99.9 | 0.015 to 0.040 | >60 | >205 | >40 | >0.040 |

| >50 | >245 | ||||||

Mechanical Property Of PVC Coated Copper Pipes

These copper pipes come with improved mechanical properties of copper with flexibility and additional features arising from the PVC coating that provide protection and absorbs the impact. This makes them suitable for use in durability demanding applications, corrosion uses and environmental protection uses.

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

PVC Coated Copper Pipes Chemical Composition

| Copper Pipe (Incl. Silver) | 99.85% Min. |

| Phosphorus | 0.013 to 0.5% |

| Total Impurities | 0.06% Max. |

Uses of PVC Coated Copper Pipe in Maldives

Manibhadra Copper Fitting Manufacturer is giving PVC Coated Copper Pipes, which are highly useful today in the Industrial as well as general areas of the Maldives. Maintaining efficiency and reliability of pipe conveyance systems is important in different operations and uses.

Industrial Applications

- HVAC Systems : Common in different HVAC systems, mainly for their thermal conductivity and resistance to corrosion.

- Oil and Gas Pipelines : Supplier of intended service life and mechanical properties for conveying oil and gas in offshore as well as onshore structures.

- Refrigeration Systems : Specified for refrigeration equipment in retail electrical stores, freezing equipment in catering industries and industrial refrigeration.

- Desalination Plants : Crucial for usage in desalination plants where there is need for transport of water since it has to withstand the effects of salt water.

- Chemical Processing : Perfect for the carriage of chemicals considering that they resist reactions with other chemicals besides being quite strong under pressure.

General Applications

- Residential Plumbing : Applied in home water systems for water distribution without contaminating water to a desirable standard within homes.

- Fire Safety Systems : Used in fire safety systems for assured water supply and to improve its durability against various factors.

- Solar Energy Systems : Used in installation of solar water systems and in other forms of solar energy systems to permit adequate transfer of heat and extended lifespan.

- Marine Applications : Ideal to use in marine conditions since they offer re-al high resistance to corrosive based environments thus improving their durability under such conditions.

PVC Coated Copper Pipes: Advantages

- Enhanced Durability : Copper and PVC give the pipes a very strong material which makes the pipes to last long especially when used in areas that have tough conditions.

- Superior Corrosion Protection : The PVC layer shields the copper busbar from rust hence can live longer despite being installed in coastal areas such as Maldives.

- Energy Efficiency : Thermal insulation properties enable products to minimize heat transfer hence improving the efficiency of heating, ventilation and air conditioning as well as refrigeration systems.

- Versatility : Our PVC Coated Copper Pipes can be ordered in a number of sizes and formats making it highly desirable in a variety of uses.

- Low Maintenance : PVC cover seems to be useful since it minimizes the times that are likely to be spent on maintenance costs in the periods of service delivery.

- Eco-Friendly : Copper is recyclable and makes our pipes to be environmentally friendly pipes for any sustainable project.